The laboratory sealed jaw crusher is named because the crushing medium in the body is a jaw plate, and it is widely used in metallurgy, mining, coal, coking and other industries. When the laboratory sealed jaw crusher works, it relies on two jaw plates to crush the material, so as to achieve the purpose of crushing. However, this equipment has working characteristics and advantages that are different from other crushing equipment.

1. Jaw plate material is available

The jaw plate of closed jaw crusher is generally made of high manganese steel, but there are also several materials such as white iron and wear-resistant alloy. Because the material that the customer is crushing has relatively high hardness. Therefore, the jaw plate must have sufficient hardness and rigidity to ensure that there will be no wear during use. At the same time, the material moisture content exceeds 8%, and the cutting material will be different. Of course, the price will be different for different materials, and it can crush materials with different hardness. If the moisture content of the material exceeds 8%, there will be a situation where the cutting material is different.

2. Sealed and environmentally friendly

The upgraded products of the laboratory sealed jaw crusher have improved in terms of materials and product structure. Moreover, in order to adapt to the increasing awareness of environmental protection, now not only the sealing performance and structural optimization are improved, but also the function of dust removal is added. The dust removal pipe can be incorporated into the original main pipe to remove the dust from the outside, and an exhaust system can also be added separately. Your working environment is clean and tidy.

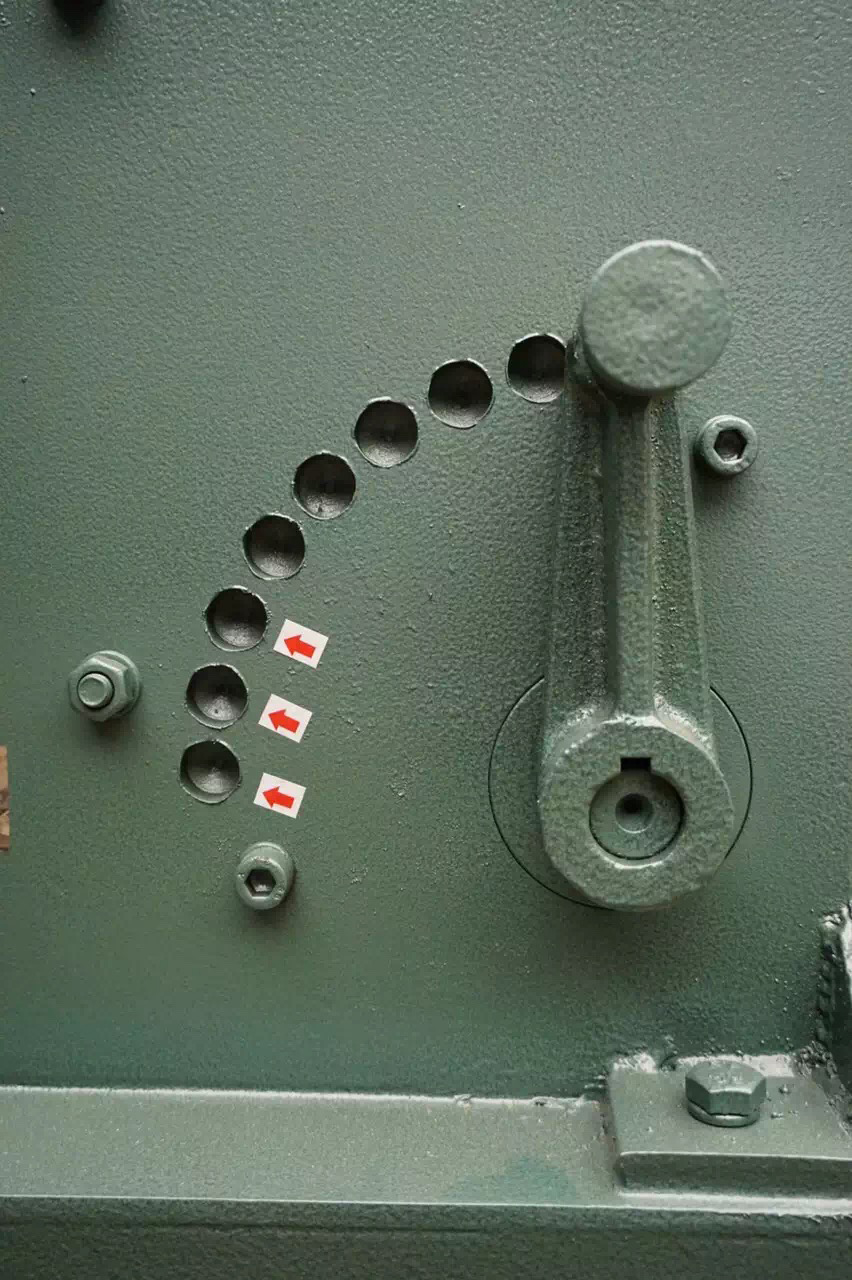

3. The output particle size can be adjusted

The particle size of the material produced by the lab mini jaw crusher can be adjusted according to the needs of the user, because there is an adjusting device in the jaw crusher, which is mainly used to adjust the discharging size, and the size is proportional to the output. The position of the support material and the clearance of the material opening can be adjusted.