0.4-40L Full directional planetary ball mill

Full directional laboratory planetary ball mill

Introduction for 360 degree planetary ball mill

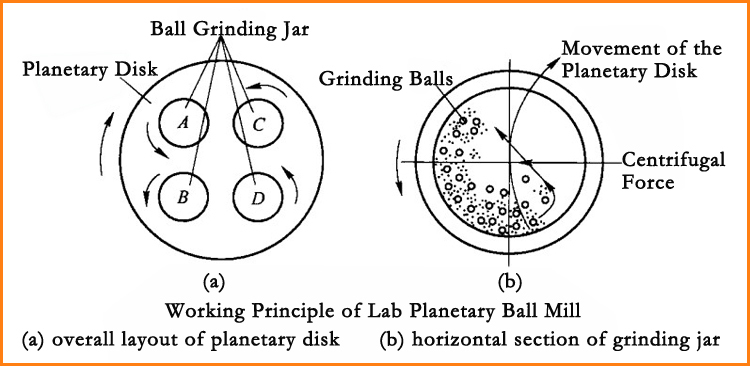

On basis of vertical planetary ball mill, the omnidirectional planetary ball mill adds the function of planetary disc overturning. While planetary disc and mill jars are doing planetary movement, they can also do 360 degree overturning in a stereo space to realize multi-directional and multi-dimensional movement of ball mill jars, and to improve degree of disordered movement of balls and materials. All material are ground inside the mill jars without dead angle, which makes grinding materials more uniform and finer. This kind of ball mill solves common issues such as sinking to the jar’s bottom and sticking to the jar's wall.

XQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental protection, and etc.

The available mill jar of industrial planetary mill

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, corundum, zirconia , stainless steel, nylon, tungsten carbide and etc.

Specification for Production type lab ball mill machine

The volume can range from 0.4L to 40L 360 degree all direction planetary ball mill machine

The application of Small gold grinding machine lab ball mill

Geology and Mineralogy: rock, gravel, sand, minerals

Ceramics: porcelain, ceramics, clay, fire clay

Chemistry: pesticides, fertilizers, salts, inorganic and organic materials

Biology: plants, leaves, freeze-dried samples

Pharmaceuticals: ophthalmologist agents, gels, creams, extracts, drugs, pastes, tablets

Metallurgy: ores

Material technology: pigments, precious materials, new materials, alloys, mechanical alloying and activating

Analysis preparation: spectroscopy, X-ray fluorescence, X-ray structure analysis, chromatography

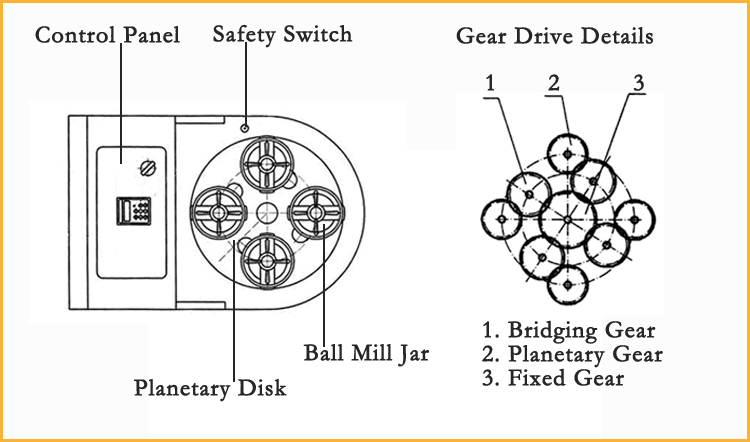

Working principle for all direction planetary ball mills 2l suppliers

Lab Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method. Minimum granularity of ground powder can be as small as 0.1μm.

Features for full directional planetary ball grinder

· High efficient super fine grinding up to end fineness<1µm

· Different speed ratios available

· Grinding jars from 100ml to 25L in different materials

· Suitable for long-term trials and continuous use

· Automatic direction reversal to avoid agglomerations

· Reproducible results due to program

· CE – certified

Packing for planetary ball mill nano 360 degree

The Lab Jar Mill will be packed export wooden box.

You Might Also Like

Send Inquiry