XCGII Dry type lab magnetic roller separator

laboratory magnetic roller separator

Description of Roll-Type Magnetic Separators

XCG-120 roller dry magnetic separation machine applies to the metallurgical, geological, building materials and other scientific research units and geological team, dry separation of weak or strong magnetic minerals, the machine uses double closed working face by magnetic circuit, excitation system, mechanical drive system and products to mine sweeping and collecting system composed of electromagnetic vibration feeder, a mineral to the sub district, by controlling the excitation current size, the mineral through magnetic gap automatically into the magnetic material and non-magnetic material discharged out of the machine, in order to achieve the purpose of separation

The rare-earth roll, generating magnetic field intensities, is very effective for concentrating or removing weakly magnetic minerals from a dry process stream.

The laboratory magnetic separator is designed to provide peak separation efficiency and is typically used when a high purity product is required. The roll is constructed of thin neodymium-boron-iron permanent magnetic discs sandwiched with thin steel pole pieces. Roll diameters typically range from 3 to 4 inches, although machines as large as 12-inches in diameter have been built and tested. The steel poles are saturated with magnetic flux and generate a magnetic field in excess of 14,000 gauss. The magnetic roll is configured as a head pulley in the separator. A thin belt, usually 3 to 20 mils in thickness, runs around this magnetic head pulley and conveys feed material to the magnetic field. When feed enters the magnetic field, the non-magnetic particles are discharged from the roll in their natural trajectory. The paramagnetic, or feebly magnetic, particles are attracted to the roll and are deflected out of the non-magnetic particle stream.

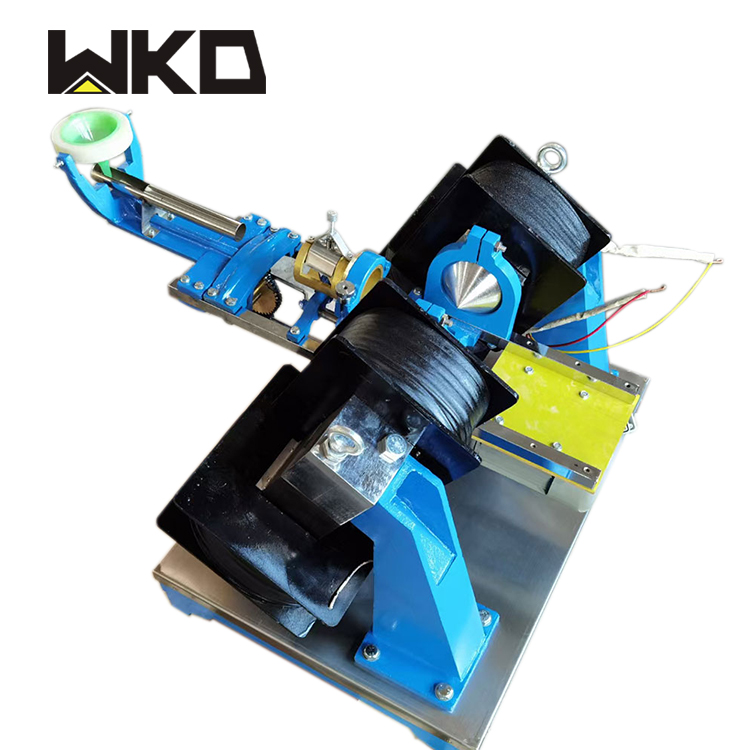

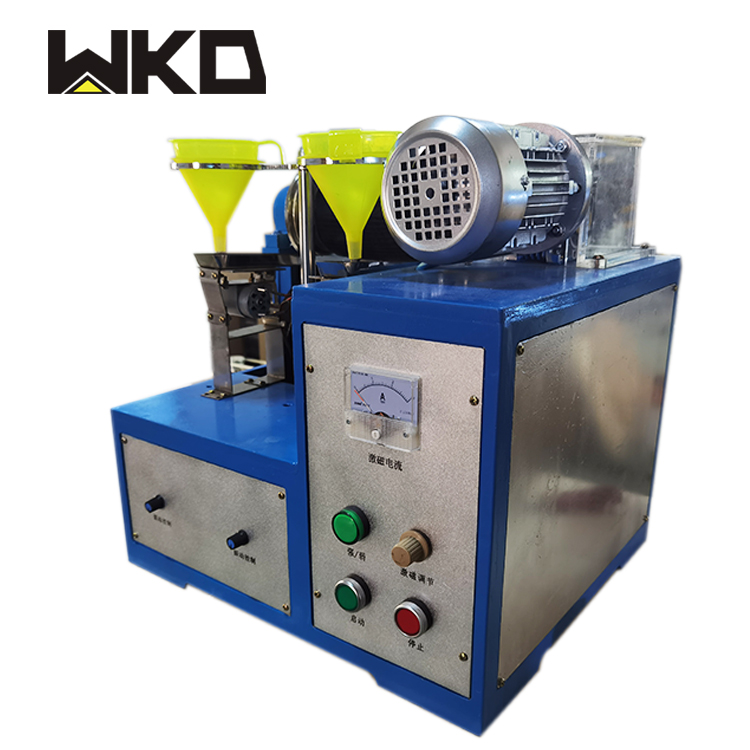

Structure for Small Magnetic Separator

The magnetic separator consists of the excitation system, the transmission mechanism, the ore feeding system and the cleaning and collecting parts of the product.

(1) excitation system: composed of fixed pole, roller magnetic pole and excitation winding and excitation DC power on both sides, the upper and lower two poles are parallel arranged. Two rollers with a diameter of 120 mm and the lower plane magnetic pole form a closed magnetic loop. Two the working distance of the magnetic pole can be adjusted by adding or reducing the cushion plate.Through the adjustment of the voltage of high-voltage machine made of silicon element supply fixed excitation winding and the DC current supply brush roller rotation pole excitation winding, can be smoothly from 2 amps to the rated value, in order to adapt to the separation of different types of ore the machine requires a range of magnetic field strength can be divided into two kinds of strong magnetic field and weak magnetic field, by the panel field selection switch selection. When the separation interval is 4mm, the magnetic field selector switch is placed in a strong magnetic field. When the excitation current is 2 AMPERES, the large magnetic field strength is no less than 14000 OE (1110RA/m).

(2) Transmission structure: consists of electromagnetic vibration feeder, ore storage funnel and ore feeding cone and baffle. The electromagnetic vibration feeder can control the amplitude of the electromagnetic vibration feeder to meet the needs of different ore particles by adjusting the two lines around the panel to control the amplitude of the electromagnetic vibration feeder. In order to adjust the speed of ore feeding, the ore bearing cone with different sizes can be used. In normal ore feeding, the baffle is adjusted to about 45 degrees, so that the ore flow is evenly distributed into the ore slot. If the ore is stopped in the middle of the way, the baffle can be stopped at the level near the ore mouth, and the ore can be stopped.

(3) Product cleaning and collection part by the product receiving chute, separating plate, hammer and mineral consisting of container cleaning brush. In the middle of the product receiving tank, a separator, magnetic products are drawn on the roll, the partition of the chute into the product of magnetic ore separator filled container, the inclination of the movable groove side by screwing the handle can be adjusted, non magnetic products by lower ore groove into another containing ore container.

Application for laboratory magnetic extractor

1)Used for dry sorting of weak or strong magnetic minerals

2)Adopting double working face closed magnetic circuit

3)Consisting of excitation system, transmission machinery feeding system and product cleaning and collecting system.

Packing for dry magnetic roller separator

The lab roller magnet will be packed export wooden box and picture as below

You Might Also Like

Send Inquiry