MZ-100 100g capacity laboratory pulveriser

laboratory sealed sample pulverizer

Introduction for laboratory pulveriser

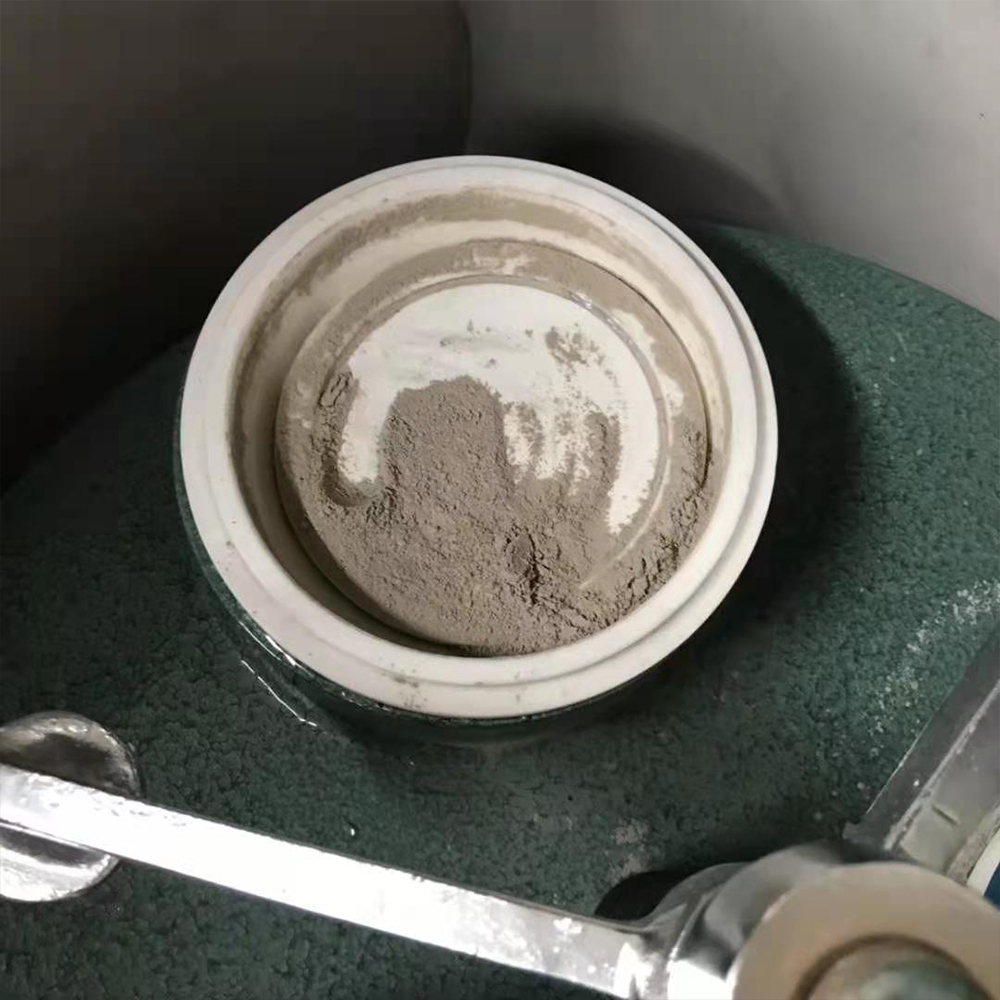

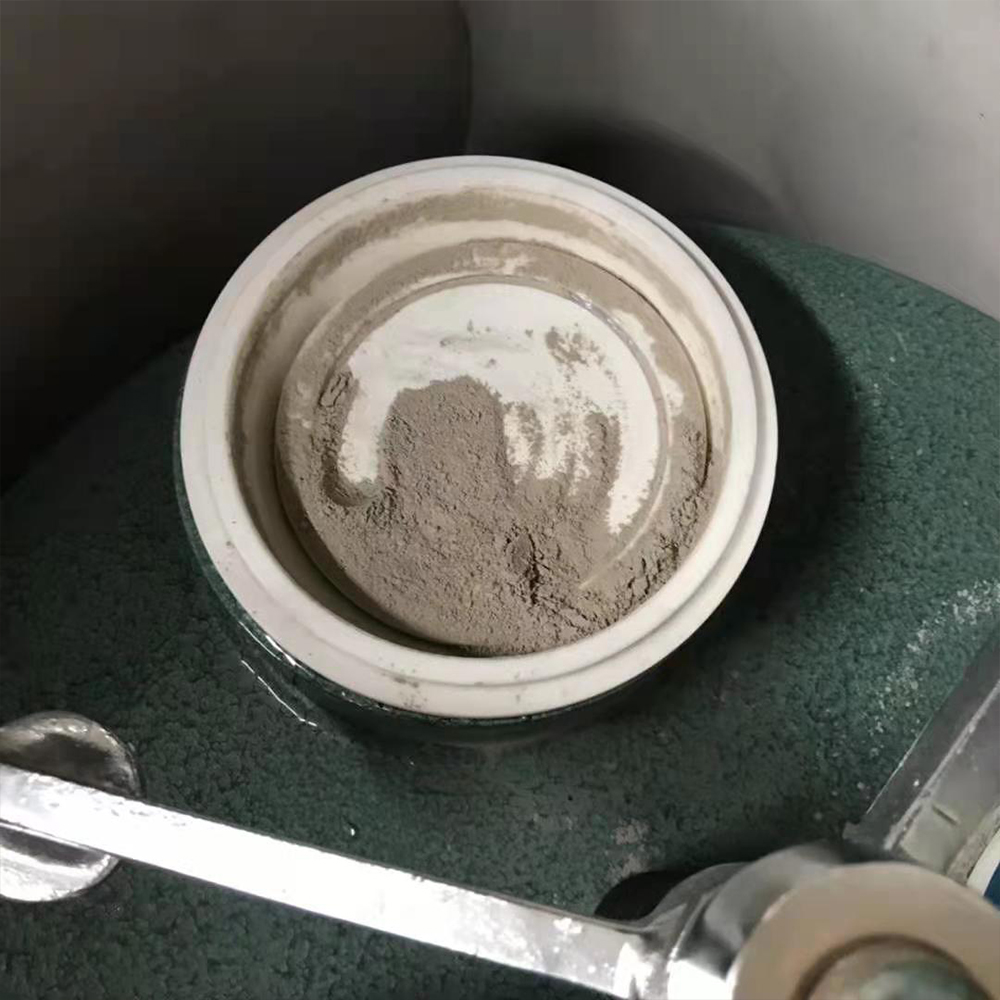

laboratory sealed sampling pulverizer mill sample grinder for lab use is a small lab grinding machine for grinding the ore/material samples into powder, which has been widely used in the laboratory of the geology, mining, metallurgy, coal, power, chemistry and building industries, for the none pollution sample testing.

Laboratory mini pulverizer is an excellent unit for reducing primary laboratory crusher or roll crusher to a fineness up to 120-200mesh in preparation.

This sample herb grinder is ideal for ore dressing, assay, chemical and industrial laboratories.

Grinding capacity of tungsten carbide pulverizer:

Various capacity: 100 g/Bowl, 200 g/Bowl, 400 g/Bowl, 500 g/Bowl,1000 g/Bowl.

Bowl material: Hardened manganese steel / Tungsten carbide / Corindon.

the widely using material is High manganese steel.

These ring grinders also come in single or multiple stations or bowls. The most common being 1 bowl but as production or sample contamination reduction might require I bowl as much a 7 bowls on one machine. The size/capacity of the bowl and its ring & puck also varies depending on how much you want to grind at the same time.

Application for mini pulverizer

Mining: For processing coal, ores or minerals for physical or chemical analysis

Metallurgy: For grinding blast furnace slag or cast iron samples to determine additives needed.

Infrared and x-ray fluorescence analysis: For preparing samples with a short grinding time without contamination through undesired abrasion.

Ceramics: For grinding rock samples to produce raw powder to determine CaO3 amd MgCO3 content or clinkers to study the constancy of the mineralogical structure

Agriculture and ecology: For preparing samples for chemical analysis of soils, sludges or vegetable matters

Working principle for pulverizer grinder

The motor drives the rotating shaft to rotate with high speed, which generates exciting vibration. Due to centrifugal force, the bowl puck and ring hits, squeezes, and grinds the sample to achieve the purpose of crushing.

Features for laboratory pulverizer

1. High efficient no need screening again, the output material could be used for testing directly.

2. Digital timing screen, special designed high quality motor, with long service life.

3. With shock-absorbing stand.

4. Sealed grinding pot, dust proof, no pollution.

5. Low noise, smooth operating, complete sealed machine, with high safety operation standard.

6. High standard sealing design, no leaking for dry or wet method grinding.

7. Reliable, evenly output size, short grinding time.

8. Simple and reasonable structure, good out look, easy to operate, maintenance, and clean.

Packing for pulverizer grinding machine

The mineral sample pulverizer will be packed export wooden box.

You Might Also Like

Send Inquiry