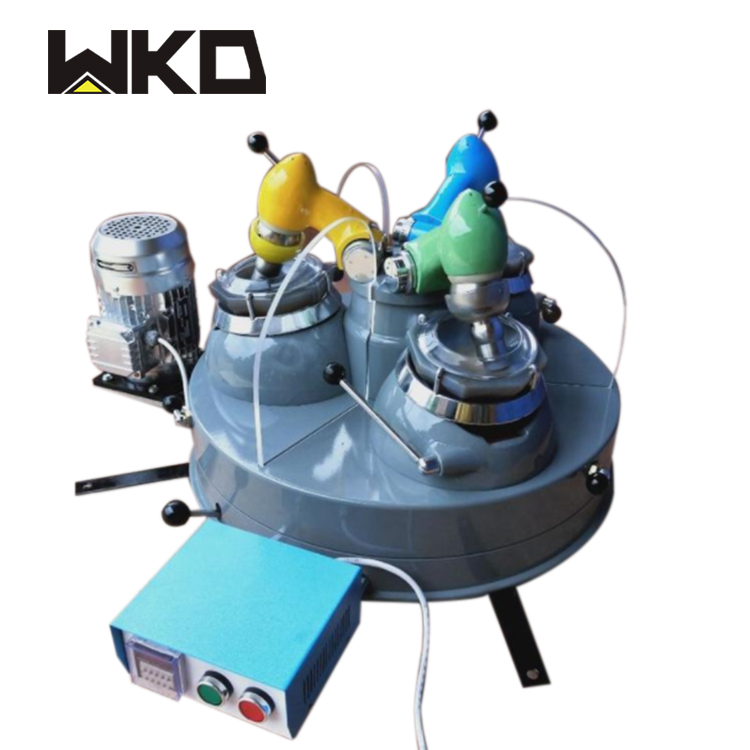

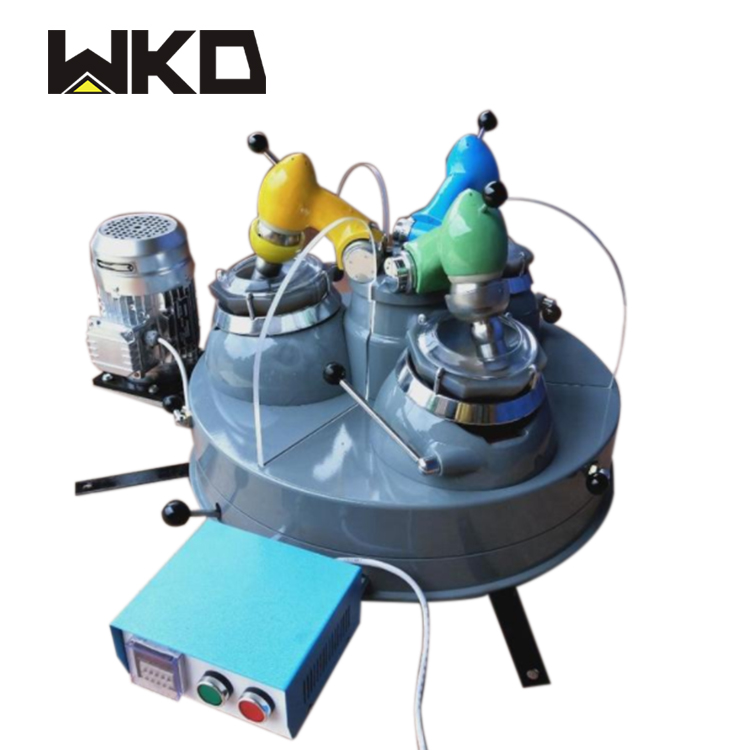

XPM 120X3 Triple lab grinding miller

Introduction for Laboratory Triple Grinding Miller

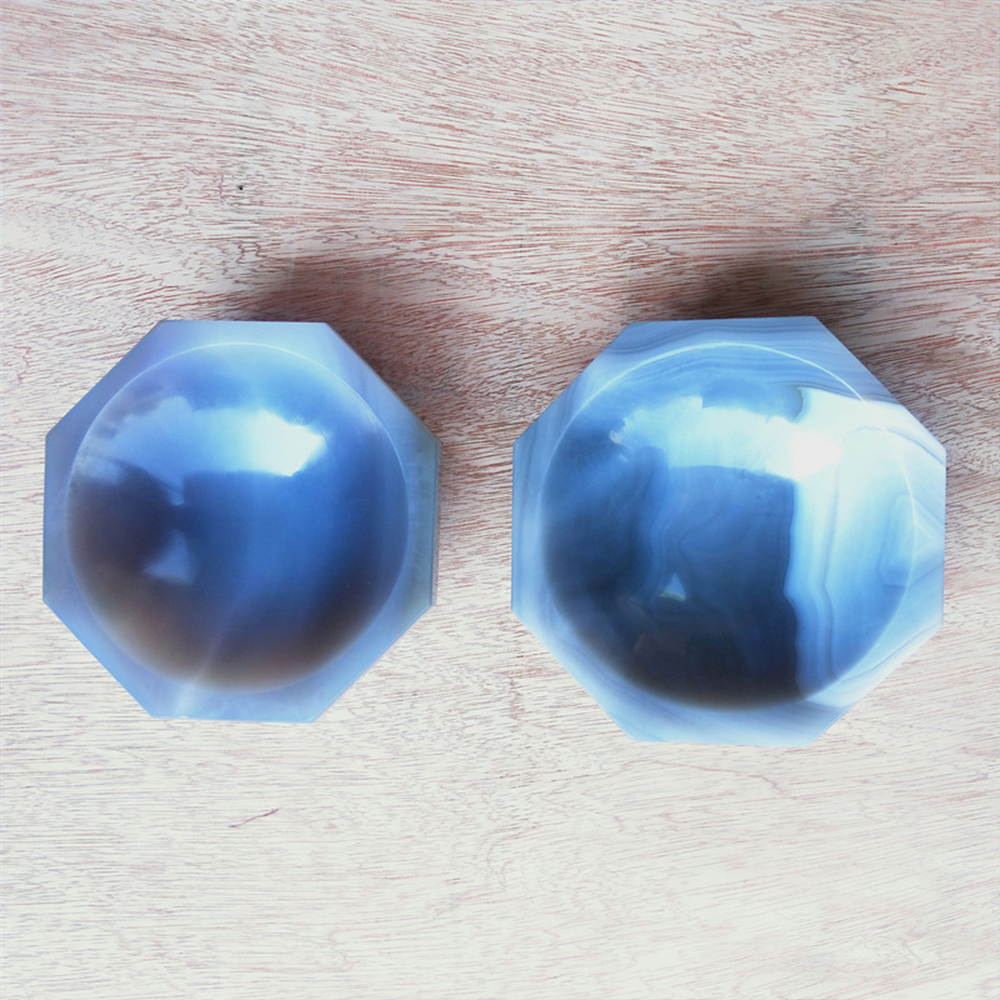

XPM 120x3 mechanical agate mortar and pestle miller is a kind of grinding equipment which mill and analyze samples through dry grinding. mechanical grinding miller are mainly used to mill and analyze samples by laboratories in departments such as metallurgy, building material, chemical, coal, water and electricity, commercial inspection, and geology. Laboratory Grinding Mill are also used to grind a small quantity of materials.

Working Principle for Laboratory Micropowder Milling Machine

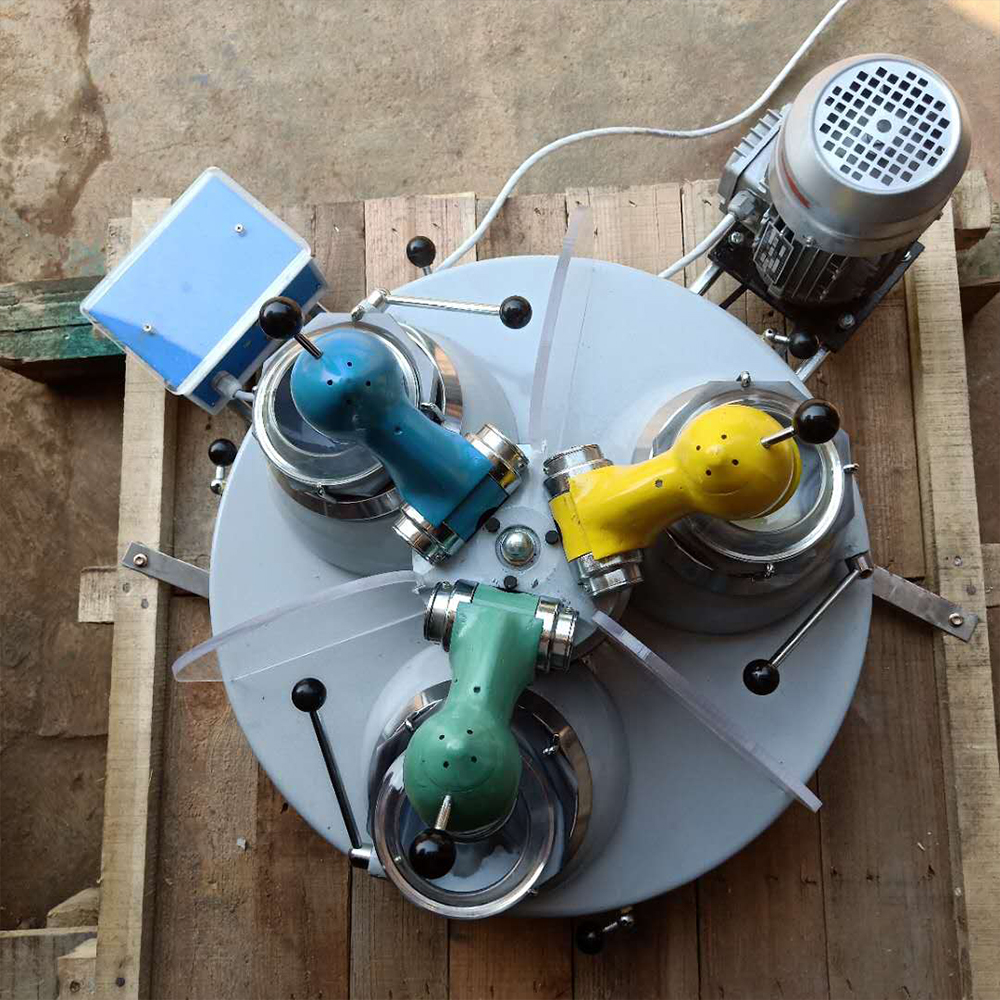

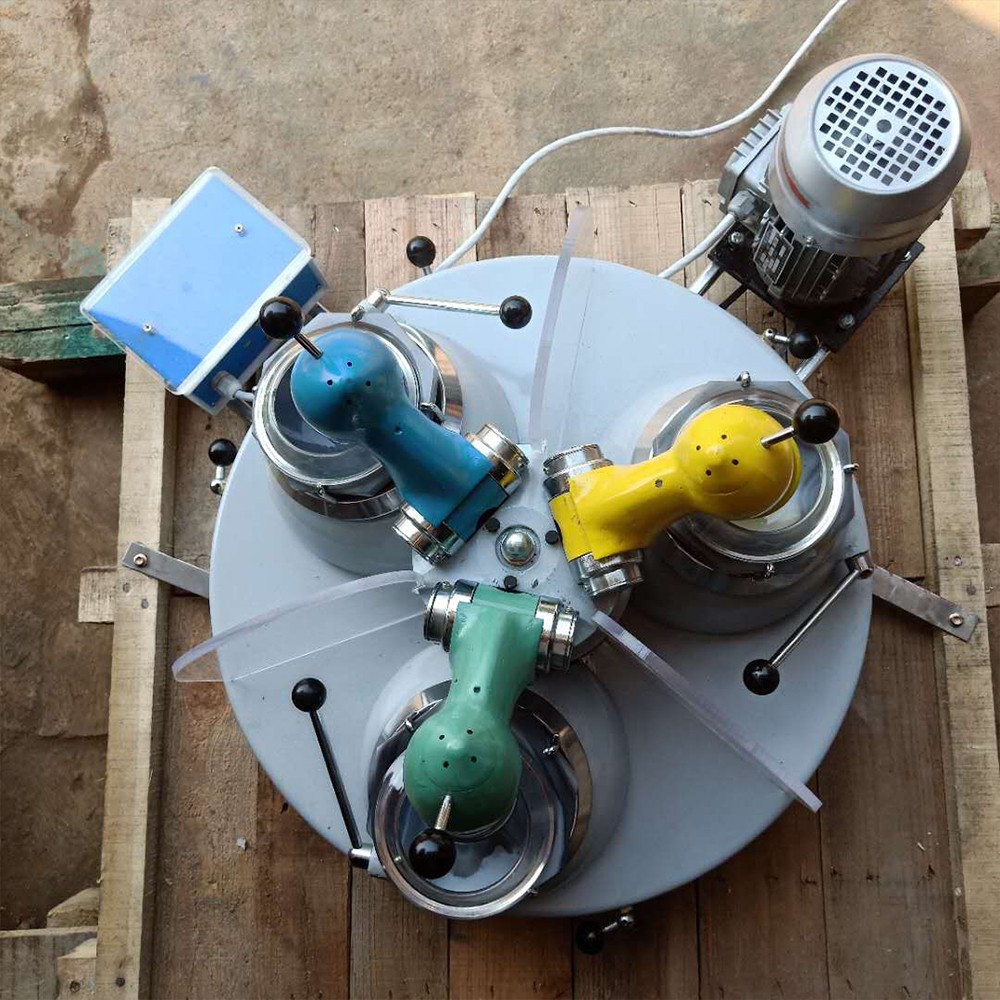

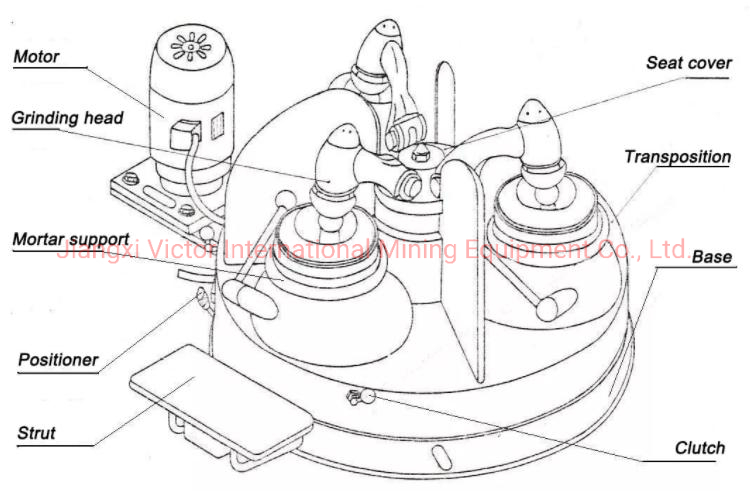

Grinding head, mortar support and clutch are evenly installed on the rotating seat and in the bearing of rotating seat, at an angle of 120 between each two of them. On the front of the base are mounted receiving support plate and electrical equipment; on its left is installed a motor.

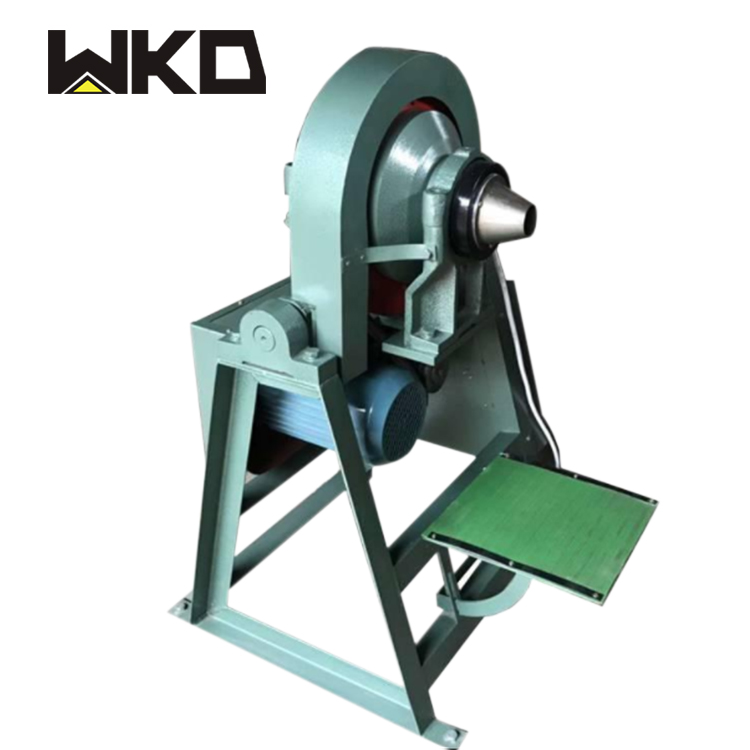

When the clutches are connected, the motor drives the rotation of the grinding head through the belt pulley, gear shaft. The other end of gear shaft and the gear of mortar support engage. Since relative sliding occurs due to clockwise rotation of grinding bar and clockwise rotation of mortar, the materials are ground through the weight of grinding head.

Structure for mortar grinder

The structure is mainly composed of three sets of grinding heads, clutch, mortar support, etc.

Operation Instruction for laboratory grinder miller machine

Grinding head, mortar support and clutch are evenly installed on the rotating seat and in the bearing of rotating seat, at an angle of 120°between each two of them. On the front of the base are mounted receiving support plate and electrical equipment; on its left is installed a motor. When the clutches are connected, the motor drives the rotation of the grinding head through the belt pulley, gear shaft, and cardan joint. The other end of gear shaft and the gear of mortar support engagement. Since relative sliding occurs due to clockwise rotation of grinding bar and clockwise rotation of mortar, the materials are grinded through the weight of grinding head.

Packing for lab grinder mill

automatic mini pestle and mortar machine will be packed export wooden box and picture as below

Next

Last pageYou Might Also Like

Send Inquiry