In the crusher equipment, there are many types of crushers, all of which have different advantages. The type and model of the equipment should be selected according to the crushed material and the degree of crushing.

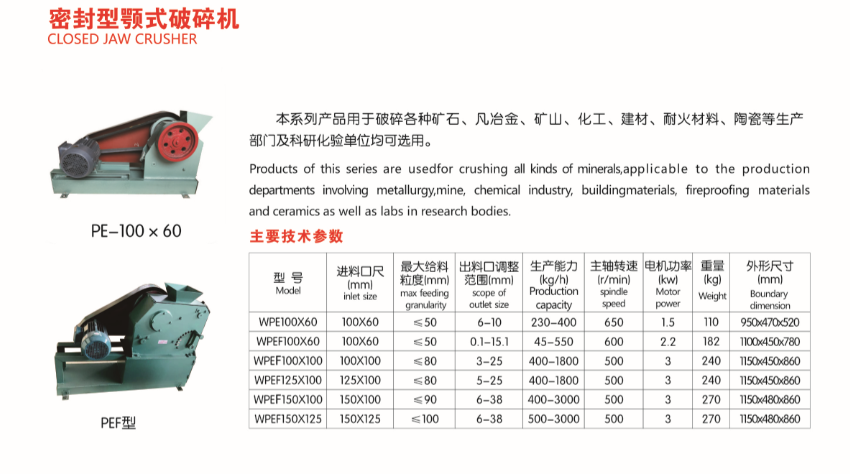

(1) laboratory Jaw Crusher

The jaw crusher is used in the laboratory to crush coal, coke, limestone, pyrite and other materials. Its crushing method is flexural extrusion type, relying on two wear-resistant jaw plates to crush the material. This machine has the characteristics of large crushing ratio, uniform particle size, convenient adjustment, fully sealed and less dust.

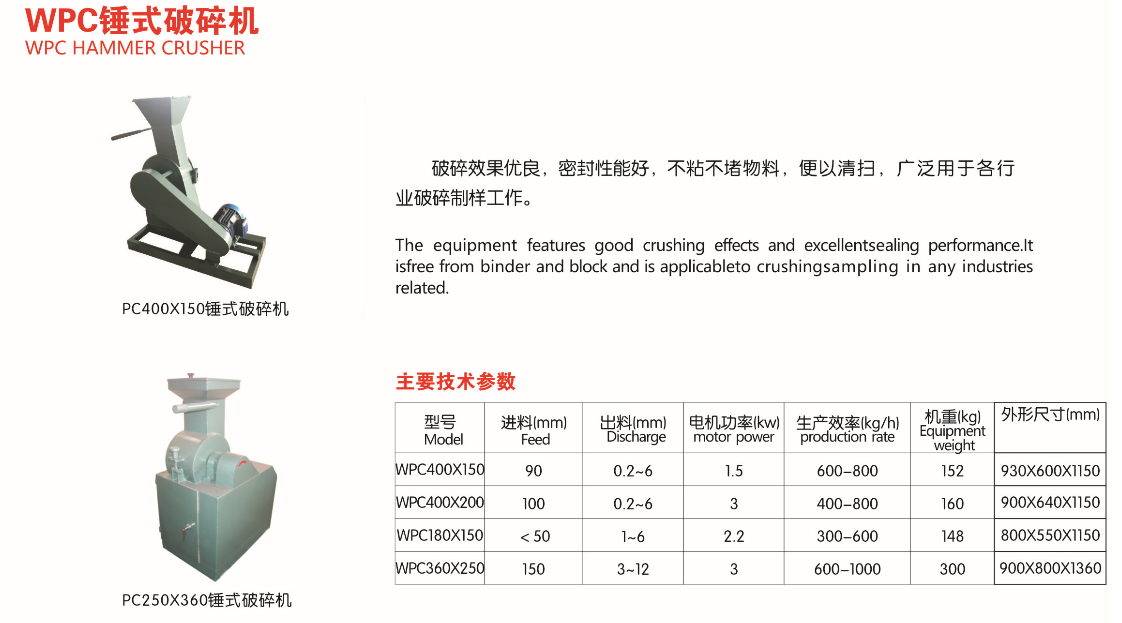

(2) laboratory Hammer Crusher

The crushing method is chopping, relying on the high-speed rotation of the wear-resistant hammer in the crushing chamber to crush the materials, and the crushed materials are in the shape of uniform and regular round balls. The broken material needs to be discharged through the grate plate, and the particle error is small.

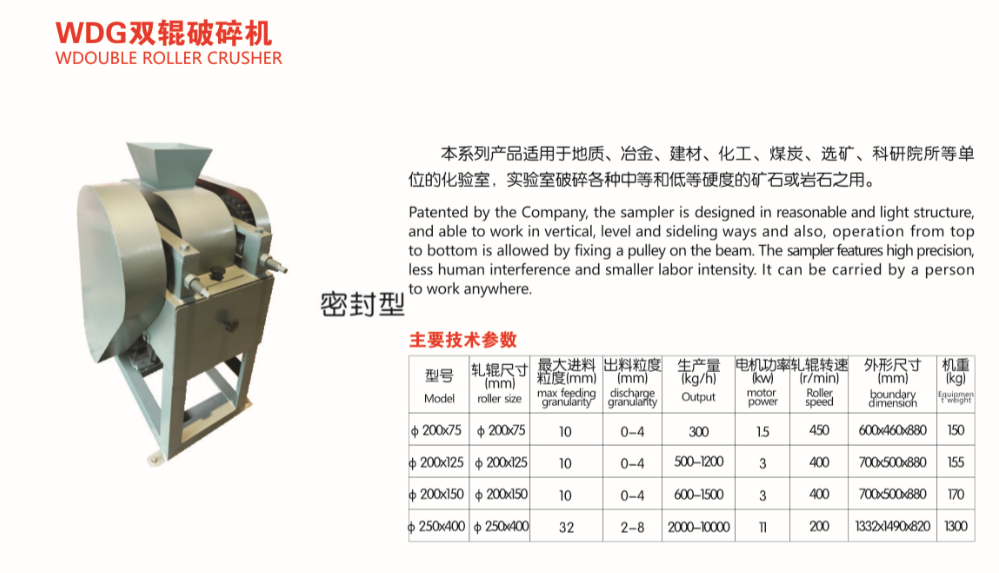

(3) laboratory Roller Crusher

This machine is used in the laboratory to crush non-metallic materials such as coal, ore, rock, etc. The machine uses two rollers to rotate relatively to crush the materials entering the crushing chamber, and then passes through the gap between the two rollers into the receiving hopper. Tune.

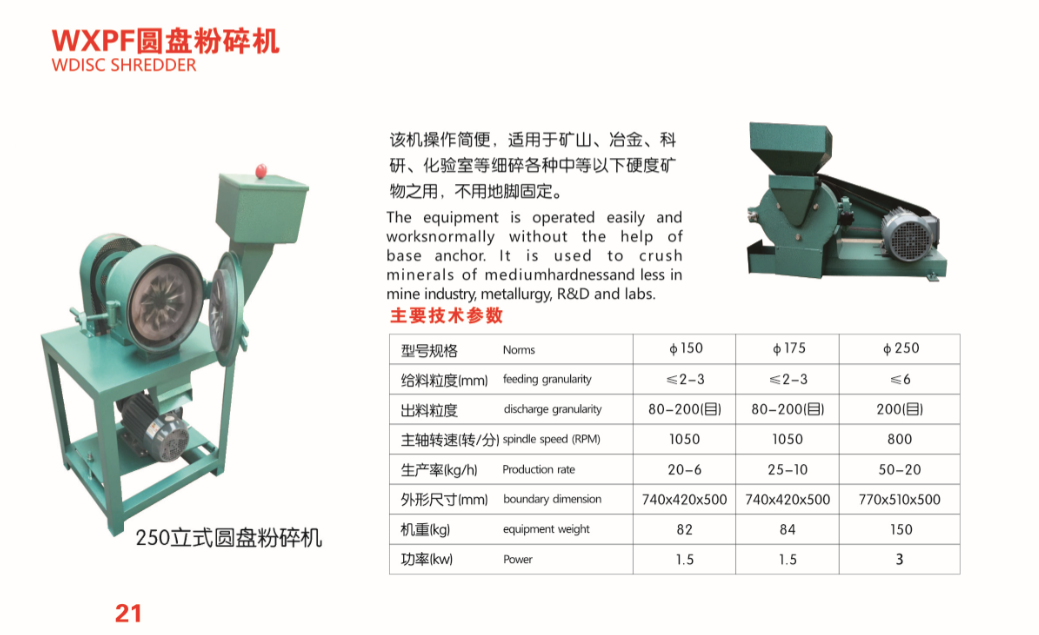

(4) laboratory disc crusher

Laboratory Disk Mill or Laboratory Disk Pulverizer can be used for intermittent and continuous fine grinding of hard-brittle and medium-hard materials in the field of mining and metallurgy, glass industry, ceramics industry.