In the laboratory, solid samples generally need to be pretreated before detection, analysis and other operations can be performed. In the pretreatment, crushing and grinding is a very important. If the fineness of crushing and grinding is not enough, the subsequent experimental data will not accurate either.

Various types of sample pulverizers are commonly used in laboratories to grind solid samples, such as laboratory sample pulverizers (vibration mills), disc pulverizers, rod mills, conical ball mills, and micro pulverizers. Each grinding equipment has its own characteristics and is suitable for different samples.

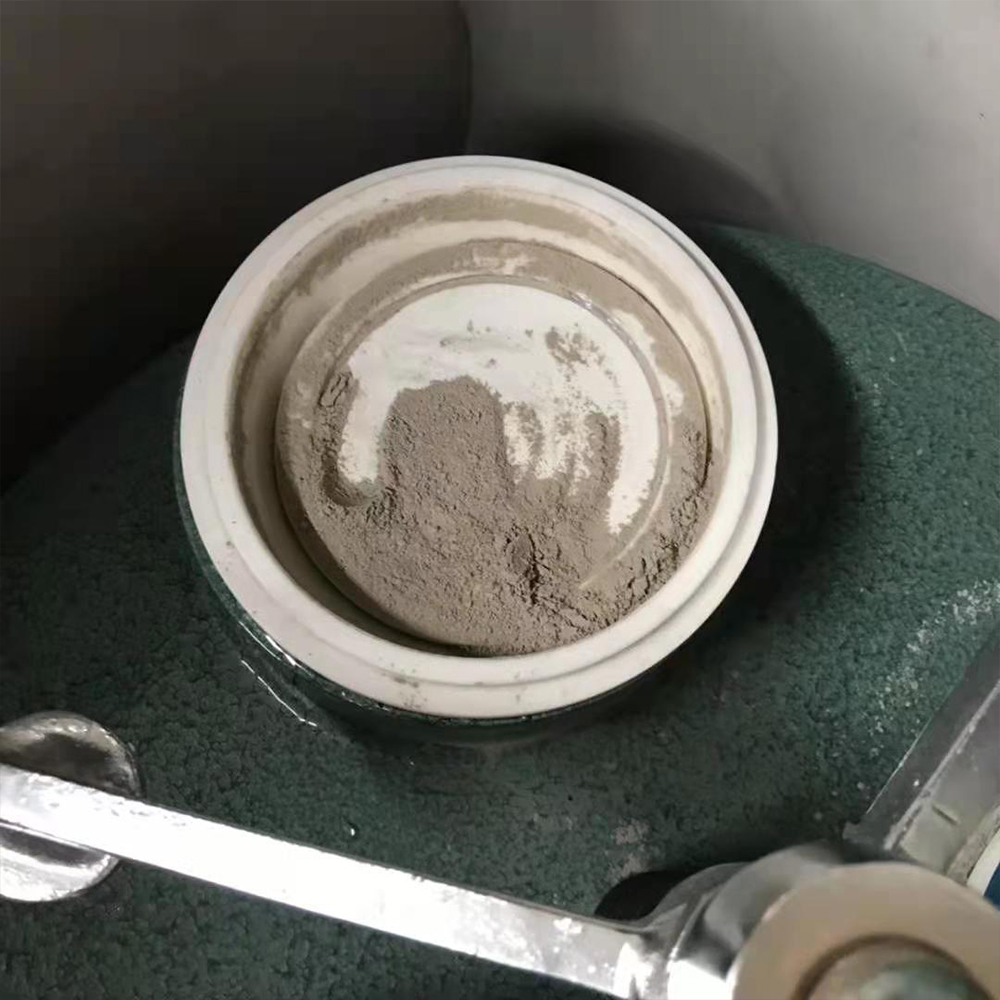

1. Sealed laboratory sample preparation pulverizer

Due to the different names in the industry, some industries also call it the vibration grinding machine. In fact, it is the same equipment, but the name is different. This machine is used for crushing hard and brittle non-metallic substances. It can quickly make materials into 100-200 mesh micropowder samples within 2-6 minutes. The fineness can reach 320 mesh, which can be directly used for laboratory tests.

2. Laboratory Disc Shredder

The disc crusher uses a pair of discs to grind materials, mainly used for medium hardness ore crushing, and is the main equipment in laboratories or laboratories in metallurgy, geology, building materials, chemical industry and other industries.

3. Laboratory Rod mill

The rod mill is suitable for the preparation of gold ore and other rock mineral analysis samples. The prepared samples have good uniformity and adopt a novel mechanical inverted sample. Cleaning, dust removal, timing and other technologies, the harm of silicon dust is small, the operation is light, the quality is stable, and the work efficiency is high.

4. Laboratory Conical ball mill

Conical ball mill is a common equipment for mineral analysis and fine grinding of ore in laboratories of metallurgical geology, coalification, building materials and other departments; it is also a supporting equipment for flotation machines and other instruments. It is small in size, convenient in operation and accurate in work efficiency.

5. Planetary ball mill

Planetary ball mill can grind coarse particles into micro powders. It can mill the materials from 3~10mm maximum into 0.1~1um minimum powder. Planetary Ball Mill Machine can deal 0.1L to 100L material per time depends on the model choose. Widely applied in industries of chemical, medical, construction, mineral, etc.