5LL-400 laboratory spiral separator

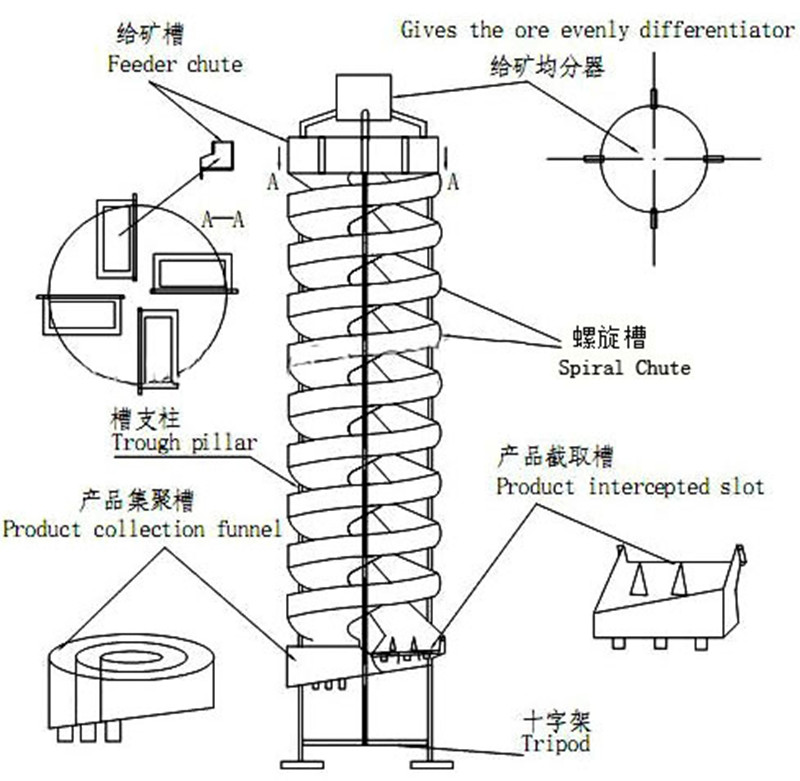

Introduction for spiral chute spiral separator

Spiral chute, a new gravity separation machine, applicable to processing iron, tin, tungsten, tantalum, niobium, gold, coal and other metal separation from particle size 0.6mm to 0.05mm.

It has been used in to enrichment the particle size 0.3-0.02 millimeters fine grain like iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal, monazite, rutile, zircon and other low-grade ores. The non-metallic minerals which have a big enough specific gravity difference.

Specification for lab spiral chute

Main Features for spiral separator machine

1. Reasonable structure and small occupation area

2. High recovery, high efficiency, and precise separation

3. Non-required power

4. Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

Working Principle for humphrey spiral separator

Spiral chute is to Use physics and a precisely designed piece of equipment, the material is discharged onto a banked metal flight which is spirally wound around a central shaft. As the material flows down the separator, its speed increases, and centrifugal force carries it toward the outer edge of the flight.

Advantage for heavy mineral spiral separator

1.Precise separation

2.Non-required of electricity

3.Light weight, anti corrosion, rust and wear resistant

4.Simple installation and minimal maintenance requirements

5.Low operating cost and long service life

6.Reliable running with minimal operator attention

7.Strong adaptability to fluctuation of feeding amount, density, size and grade

Previous

first pageNext

Last pageYou Might Also Like

Send Inquiry